BASF AG:Bacteria as a chemical plant

Advertisement

BASF is the first company to decipher the genetic information of the bacterium Corynebacterium glutamicum and has applied for comprehensive patent protection. This was achieved in cooperation with the biotechnology company Integrated Genomics, Inc., Chicago. The partners have also determined the entire metabolism of the bacterium. Corynebacterium glutamicum is of high economic interest as a research object because it is used by the chemical industry for the biotechnological production of the amino acid lysine, among other things. The substance is employed as a source of protein in animal nutrition. BASF wants to use the new findings on the genetic information and metabolic pathways of the bacterium to make its biotechnological production of lysine even more efficient.

Lysine is one of the essential amino acids in animal nutrition. Lysin produced using biotechnology is added to feed concentrates as a source of protein, and is an alternative to soybeans or meat and bonemeal. In 2000, more than 450,000 metric tons of lysine were sold worldwide, representing a value of about € 660 million. The Fine Chemicals division produces lysine at its Kunsan, Korea, site and is one of the world's biggest three producers.

The genome of Corynebacterium glutamicum, in other words the sum of all genetic information, embraces more than three million base pairs. BASF and Integrated Genomics succeeded in putting together these "letters" to make sensible "words", or individual genes. The entire genome was deciphered in this way. "Some genes were known, others had already been patented by competitors," explains Dr. Markus Pompejus, head of the lysine research project at BASF. "However, we found about 1,500 unknown genes, determined their function and have filed patent applications for them."

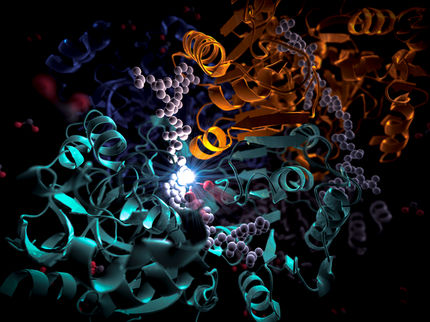

Starting from this information, BASF and Integrated Genomics investigated the metabolism of Corynebacterium glutamicum. In biotechnological production, the microorganism is fed with sugar. It is then allowed to breed at controlled temperatures and with a plentiful supply of oxygen, and finally the lysine produced is harvested. BASF can now trace the entire metabolic pathway by which the bacterium converts the sugar step by step into the amino acid. The researchers also know the enzymes - these are organic compounds formed by the bacteria, each of which controls a certain reaction step. The partners also found out which genes contain the information for producing these enzymes. "This is the starting point for optimizing our production strain," explains Pompejus. "We now know which screws to turn in order to improve, for instance, the utilization of our starting materials." The researchers have already made the first amendments, and the results are being examined. Pompejus says: "Within this year, we will make significant improvements to the process starting this year."

Most read news

Topics

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.