Ener1 Nanotech Unit Prepares to Commercialize Revolutionary Battery Electrodes

Advertisement

Ener1, Inc. announced that its NanoEner, Inc. subsidiary has established and equipped a pilot nanotechnology-based manufacturing facility to fabricate electrodes for high discharge rate, lithium-ion batteries. The company's battery subsidiary, EnerDel, Inc., in which Delphi Corporation holds a 19.5% interest, is in discussions with automotive OEMs regarding evaluation of samples for use in hybrid electric vehicles where the high discharge rate characteristic is viewed as key to performance and cost. EnerDel also plans to explore applications of this technology in other markets.

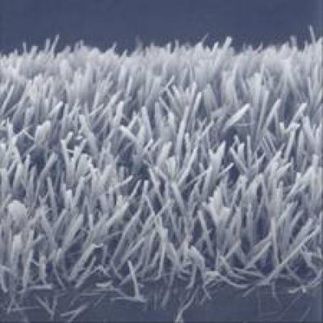

The company's new nanotechnology based manufacturing process can be used to produce electrodes (anode and cathode) with substantially more power output and higher discharge rates, as well as much faster recharging times. The company believes that its proprietary nanotechnology process for producing electrodes, which is based on its proprietary vapor deposition process and equipment, represents a major innovation in battery technology that could greatly improve performance in many existing and emerging battery-powered applications.

The Company's new facility has three beta-phase apparatus stations with specially designed software-based controls for continuous fine-tuning and monitoring of all aspects of the vapor deposition-based, nanoproduction process, which allows maintenance of desired electrode structures to the nano level. All of the proprietary production equipment and related-nanotechnology processes used in the facility were designed by the company's scientists and engineers.

Other news from the department research and development

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.