Scientists determine strength of 'liquid smoke'

Advertisement

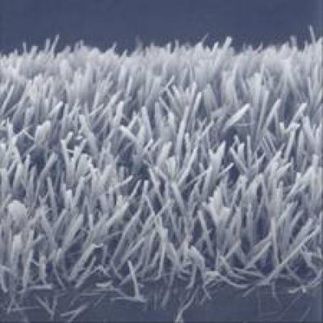

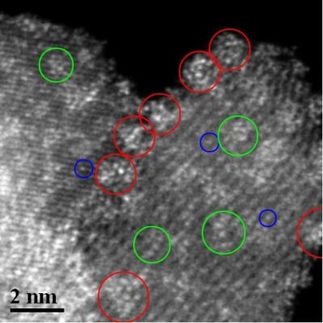

Researchers have created a 3D image of a material referred to as "liquid smoke." Aerogel, also known as liquid smoke or "San Francisco fog," is an open-cell polymer with pores smaller than 50 nanometers in diameter. For the first time, Lawrence Livermore and Lawrence Berkeley scientists have peered into this material and created three-dimensional images to determine its strength and potential new applications.

Aerogel is a form of nanofoam, an engineered material designed for high strengh-to-weight ratio. Such nanofoam structures are also present in the fields of geology, phospholipids, cells, bone structure, polymers and structural materials, wherever lightness and strength are needed. These mesoporous (2-50 nanometer-sized pores) crystalline materials can be used as catalysts for cleaner fuels and for the diffusion of water and oil in porous rocks. The structure and diffusion properties of nanofoams are determined by their structure.

Aerogels have the highest internal surface area per gram of material of any known materials because of its complicated, cross-linked internal structure. They also exhibit the best electrical, thermal and sound insulation properties of any known solid. It's not easy to see inside aerogel to determine the topology and structure at nanoscale-length scales because the smallest pore is normally too small to be observed internally by any conventional microscope.

But Livermore scientist Anton Barty and Lawrence Berkeley researcher and former LLNL scientist Stefano Marchesini were determined. They inverted coherent X-ray diffraction patterns to capture the three-dimensional bulk lattice arrangement of a micron-sized piece of aerogel.

"By imaging an isolated object at high resolution in three dimensions, we've opened the door to a range of applications in material science, nanotechnology and cellular biology," Barty said.

The new research shows that the lattice structure within aerogel is weaker than expected. The researchers saw a structure made up of nodes connected by thin beams.

"This blob and beam structure explains why these low-density materials are weaker than predicted and explains the high mass scaling exponent seen in the materials," Barty said.

In the future, the 3D analysis could be applied to other porous materials and could help modeling filtration problems such as oil and water in minerals, Barty said.

Most read news

Other news from the department science

These products might interest you

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.