Transform plant waste into next-generation safe batteries

Plant-based hydrogel tames zinc dendrites, pushes aqueous batteries past 1 000 stable cycles

Advertisement

Aqueous zinc-ion batteries promise safe, low-cost energy storage, but metallic zinc grows needle-like dendrites that short-circuit cells within a few hundred cycles. Now, a purely plant-derived hydrogel appears to solve the problem without resorting to toxic additives or expensive ceramics.

The team dissolved microcrystalline cellulose in an alkali/urea ice bath, then stitched the polymer together with borax to form the primary network. Into this scaffold they embedded TEMPO-oxidised cellulose nanofibres—ribbon-like strands 3 nm thick and hundreds of nanometres long that carry dense carboxyl groups. The nanofibres act as both mechanical rebar and ionic expressways: molecular-dynamics simulations show Zn2+ diffusion along the composite climbs to 4.59 × 10-4 m2 s-1, almost double that of plain cellulose.

Mechanical tests reveal the optimised film—only 1 mm thick—hits 0.57 MPa tensile strength after soaking in 2 M ZnSO4, four times tougher than the cellulose-only control yet still 62 % transparent. Symmetric Zn//Zn cells cycled at 0.5 mA cm-2 survive 1 100 h without sudden voltage drop, while commercial glass-fibre separators fail after 120 h. Even at 10 mA cm-2 the hydrogel endures 650 h, and a 45 °C oven test shows four-fold longer life than the liquid benchmark.

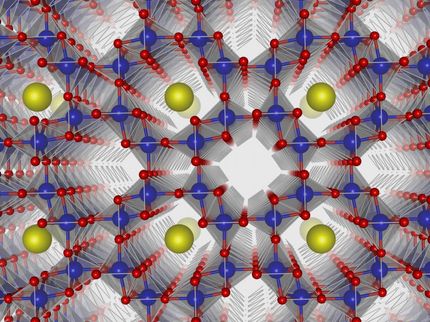

When paired with a NaCl-pre-treated V2O5 cathode, full cells deliver 237 mAh g-1 at 0.2 A g-1 and keep 79.9 % of their capacity after 1 000 cycles at 1 A g-1; liquid electrolytes fade to 69.4 %. Post-mortem AFM images show the protected zinc surface stays smooth (Ra ≈ 52 nm) whereas the liquid counterpart grows rough dendritic nodules (Ra ≈ 108 nm).

Crucially, the material is designed for real-world manufacturing. All ingredients—cellulose powder, bamboo pulp, borax and ZnSO4—are commodity chemicals, and the gel can be cast on rolls like papermaking. Costings show 1 cm2 of the bio-gel costs only 8 % of a commercial glass-fibre separator, while cellulase digestion disposes of it within four hours, offering an end-of-life route conventional membranes lack.

Flexible pouch cells built with the electrolyte continue to power a timer while bent to 90° under a 2 kg weight, hinting at wearables or e-textile uses. The authors say the same cross-linking chemistry should work with sodium or aluminium salts, potentially widening the sustainability dividend to other post-lithium chemistries.

With funding agencies in China backing scale-up trials, the cellulose hydrogel looks set to leave the lab and enter pilot coating lines—turning abundant plant waste into the quiet guardian of next-generation safe batteries.

Original publication

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.