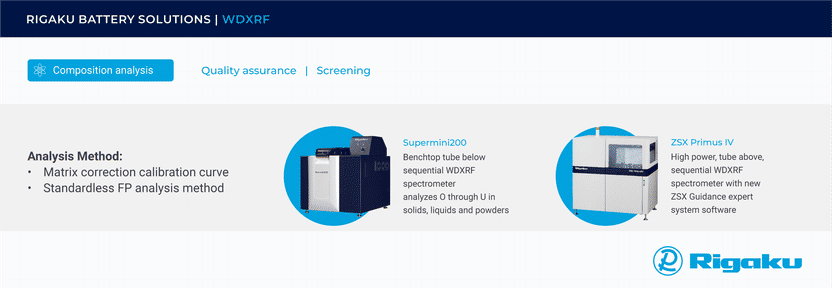

X-ray fluorescence spectrometers:

Battery research solutions

Unlock Battery Potential with Cutting-Edge Instrumentation

In-Depth Material Analysis

Material Quality Control

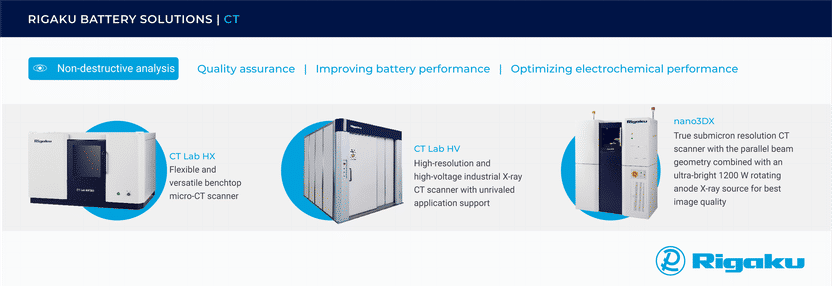

3D Imaging for Efficiency

Advance Your Battery Research with Innovative X-Ray Technologies

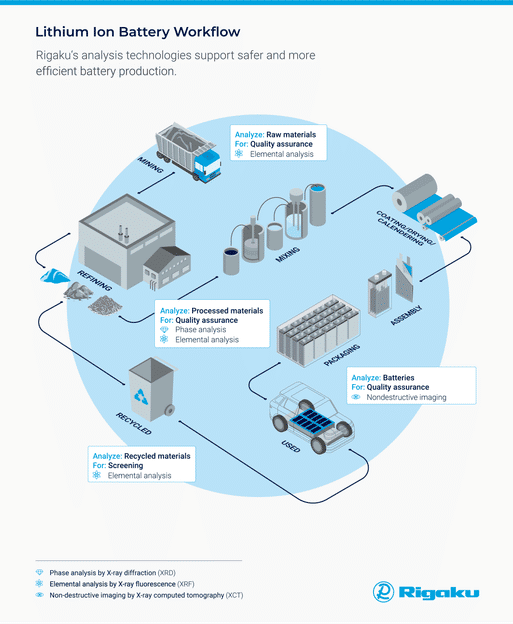

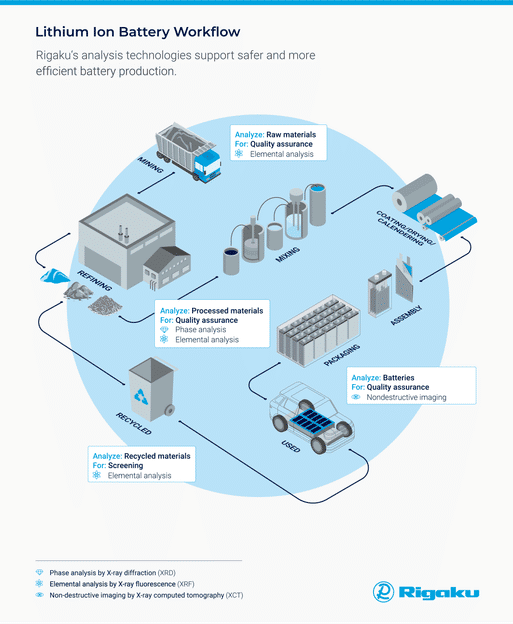

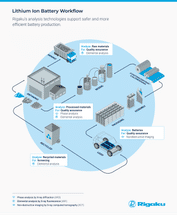

Rigaku offers solutions for characterization and quality assurance across the entire battery value chain, focusing on enhancing the performance and safety of batteries for electric vehicles.

The research examines the impact of cathode and anode materials on efficiency and the interactions between electrodes and electrolytes during charge and discharge cycles. Rigaku’s XRD instruments analyze the structure and composition of battery types like pouch cells, button cells, and solid-state batteries. Special sample holders for gas- and moisture-sensitive materials enable detailed characterizations through in-operando measurements.

In battery manufacturing, key stages include powder reception, battery material coating, and cell production. WDXRF technology allows non-destructive and precise elemental analysis, detecting main components and impurities in the ppm range for NMC cathode material. Additionally, XCT analysis can determine the porosity of Cu foils coated with cathode material. As sustainability grows in importance, XRF enables efficient analysis of black mass, supporting material recovery.

Founded in Tokyo in 1951, Rigaku is a world-renowned provider of analytical and industrial measurement technology. With more than 1,800 employees in over 60 countries, Rigaku serves diverse industries such as pharmaceuticals, biotechnology, semiconductor manufacturing and environmental sciences. Rigaku's products, which include X-ray diffraction, X-ray fluorescence spectrometry, Raman spectroscopy and computed tomography, are used for material characterization, quality control and process optimization.

1

Lithium Ion Battery Workflow

2

X-ray diffraction for crystallographic analysis

3

X-ray fluorescence for elemental quality control

4

CT imaging for multilayer cell analysis

Request information about Battery research solutions now

X-ray fluorescence spectrometers: Battery research solutions

Unlock Battery Potential with Cutting-Edge Instrumentation

Product classification Battery research solutions

Product categories

Applications

Manufacturers of similar products

Advertisement

Webinars by Rigaku

Find more X-ray fluorescence spectrometers and related products

Find Battery research solutions and related products in the theme worlds

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.