Rapid spectroscopic process analysis

Empowers development and control of flexible production processes

Advertisement

Global competition in the chemical industry, with increasingly dynamic markets and product cycles, requires shorter process development times and flexible and efficient production processes.

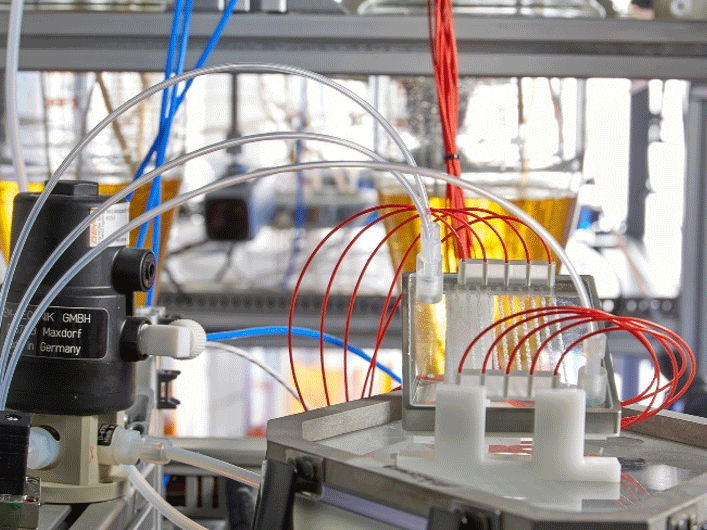

Spatially resolved spectroscopic process analysis in microreactors using pushbroom-imaging and fiber optics.

Fraunhofer ICT

By combining micro chemical engineering and spectroscopic process analysis in different spectral ranges, the time-to-market can be shortened, and an extremely fast and systematic screening of a variety of process conditions can be achieved. Due to the compact equipment size, processes can be monitored spectroscopically with a high temporal and spatial resolution. The statistical design of experiments, and chemometric evaluation methods that help to obtain quantitative information on the product composition, enable the quick and reliable identification of safe and economical process conditions.

Data-based control of chemical processes

The increasing demand for flexible production processes requires both configurable modular process technologies and also innovations in process control and automation. Instead of fixed models and rigid operations, shifting production campaigns demand process control based solely on knowledge and data - ideally in real-time. Individual sensors integrated into the process chain do not provide sufficient information. Instead, innovative inline or online analytical methods, especially rapid spectroscopic measurement methods, are needed. Individually or in combination, these methods generate information on product composition and are actively integrated into process management and control. This also contributes to process safety, because critical process conditions are identified and corrected at an early stage.

At the Fraunhofer Institute for Chemical Technology ICT, process analytical measuring systems are developed based on spectroscopic analysis techniques, and adapted to chemical processes. They help to generate the necessary information about diagnostics, optimization, surveillance and active process control. Vibrational spectroscopy (Raman, mid-infrared and near-infrared spectroscopy) and absorption spectroscopy (UV/Vis) are used.

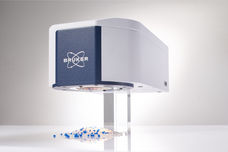

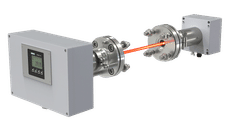

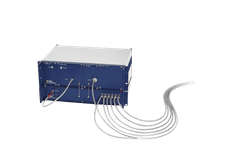

At the ACHEMA, the leading show for the process industries, Fraunhofer ICT will present a selection of its developments in process spectroscopy at the joint booth of the Fraunhofer-Gesellschaft. These include state-of-the-art imaging methods which collect spectral data (UV/Vis) within a defined reactor section, novel quantum cascade lasers which make measurements more sensitive than ever before in the MIR range, and MIR process spectrometers enabling multiplex spectroscopy at numerous points in the process through the use of optical fibers.

Most read news

Topics

Organizations

Other news from the department science

These products might interest you

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Spectroscopy

Investigation with spectroscopy gives us unique insights into the composition and structure of materials. From UV-Vis spectroscopy to infrared and Raman spectroscopy to fluorescence and atomic absorption spectroscopy, spectroscopy offers us a wide range of analytical techniques to precisely characterize substances. Immerse yourself in the fascinating world of spectroscopy!

Topic World Spectroscopy

Investigation with spectroscopy gives us unique insights into the composition and structure of materials. From UV-Vis spectroscopy to infrared and Raman spectroscopy to fluorescence and atomic absorption spectroscopy, spectroscopy offers us a wide range of analytical techniques to precisely characterize substances. Immerse yourself in the fascinating world of spectroscopy!

Topic world UV/Vis spectroscopy

UV/Vis spectroscopy is a powerful tool in analytics. It uses the ultraviolet and visible light spectrum to measure the absorption of molecules, providing insights into their structure and concentration. Whether determining protein concentrations, characterizing compounds or monitoring chemical reactions, UV/Vis spectroscopy provides accurate and reproducible data.

Topic world UV/Vis spectroscopy

UV/Vis spectroscopy is a powerful tool in analytics. It uses the ultraviolet and visible light spectrum to measure the absorption of molecules, providing insights into their structure and concentration. Whether determining protein concentrations, characterizing compounds or monitoring chemical reactions, UV/Vis spectroscopy provides accurate and reproducible data.