Natcore Scientists Build World's First Black Silicon Solar Cell Using Scalable Production Process

Advertisement

Scientists at Natcore Technology Inc. have created the world's first black silicon solar cell using processes amenable to low-cost mass production.

After recently treating a wafer to make it the "blackest" silicon solar cell surface ever recorded, Natcore's technicians used their scalable liquid phase deposition (LPD) process to create the black silicon solar cell, from wafer to finished cell, in their R&D Center in Rochester, N.Y.

In July Natcore completed a $2.5 million financing to enable the company to take its black silicon technology to commercialization. A portion of the proceeds was invested in the brainpower and lab equipment needed to execute its work quickly and in-house. "This black silicon solar cell, made entirely in our lab, is the first fruit of that investment," says Chuck Provini, Natcore President and CEO.

While Natcore's "Absolute Black" silicon wafers have near-zero reflectivity, meaning that virtually 100% of the light that reaches them is available for conversion to electricity, these wafers are merely components of a solar cell; they do not generate electricity until fashioned into solar cells.

The next stop for Natcore's new solar cell is NREL, with which Natcore has a Cooperative Research & Development Agreement (CRADA). NREL recently produced solar cells with an efficiency of 18.2% using processes that are less suited to mass production. Under the terms of the CRADA, NREL and Natcore will work together using Natcore's low-cost passivation technology to achieve or exceed that efficiency with Natcore's black silicon solar cells.

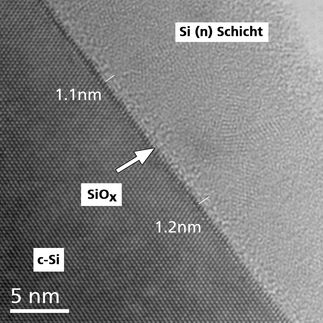

This goal would be accomplished by combining Natcore's patented LPD technology with NREL's technologies for creating a black silicon antireflective layer integrated into high-efficiency solar cells. The feasibility of the combined technologies working together has already been demonstrated in a preliminary Natcore/NREL effort that produced a small-area, lab-scale black silicon solar cell with 16.5% efficiency.

Dr. Hao-Chih Yuan, NREL Research Scientist, says "We have a good synergy with Natcore on black silicon technology. A silicon surface, without proper coating, is detrimental to the energy conversion efficiency of the solar cell. It is not unusual to grow silicon dioxide coatings on black silicon surfaces for this purpose, but the growth is typically at very high temperatures. Natcore's coating uses chemistry. They are the ones who can passivate a black silicon surface cheaply."