Scientists Grow Thermoelectric Cobaltate Thin Films on Silicon

Advertisement

thin films made of so-called thermoelectric materials could be used to convert heat directly into electric energy, or vise versa, for a variety of applications, including micro-chip-based chemical and biological sensors and more-efficient ways to cool computer chips. Thermoelectrics also hold promise for clean-energy generation because they transform heat into electrical energy without producing carbon dioxide or other emissions.

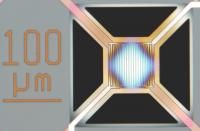

Until now, the development of these applications has been limited by certain properties of conventional thermoelectric materials and by the lack of an economically viable fabrication process. But scientists at the U.S. Department of Energy's Brookhaven National Laboratory have demonstrated the feasibility of growing high-quality thermoelectric thin films with superior properties on ordinary silicon wafers - an accomplishment that offers the promise of using available state-of-the-art silicon fabrication technology to create many new useful devices. A paper on this research was published online on February 16, 2005, by the journal Applied Physics Letters.

"Being able to grow this material on a silicon substrate means it's feasible to fabricate devices using conventional silicon technology instead of having to devise a brand-new manufacturing system for thermoelectrics. This makes the idea of using thermoelectric materials for practical applications much more economically viable than had previously been possible," said Brookhaven materials scientist Qiang Li, author of the paper.

The thin-film thermoelectric material the Brookhaven team has produced, Ca3Co4O9, is from a family of layered cobaltates recently found to have high thermoelectric power. Unlike most conventional thermoelectric materials - which melt or decompose at moderate temperatures, are easily destroyed by oxidation, and often contain harmful or rare elements - the cobaltates have high melting points and excellent chemical stability. The scientists used pulsed laser deposition methods for growing cobaltates films on commercial silicon wafers without any chemical pre-treatment of the substrate or buffer layers. The high-quality films exhibit superior thermoelectric properties.

"In addition," said Li, "we discovered that nearly perfect crystalline structures of the Ca3Co4O9, film can be formed on top of an amorphous silicon-oxide layer, which rarely happens in the crystalline thin-film growing process. Such surprising and intriguing phenomena, together with the self-assembly nature of the cobaltates, open an inviting area for fundamental research."

In addition to having a tremendous potential impact on the science and technology of thermoelectric materials used in clean-energy conversion these materials could yield important electronics applications. For example, says Li, "We can study the chemical reaction of various materials 'painted' on a small silicon chip controlled by thermoelectrics. This so-called thermochemistry-on-a-chip can be automated to be a highly efficient way to control the process of a chemical reaction by rapid cooling and heating, or to identify certain substances used in chemical weapons."

Similarly, scientists could investigate the biological behavior of DNA and manipulate proteins by regulating localized temperature changes on DNA microarrays, a device known as a bio-thermoelectric chip.

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.