Making cars and airplanes cheaper, safer and more efficient

DFG funds 2 major instruments to test components made of fiber-reinforced composites

Advertisement

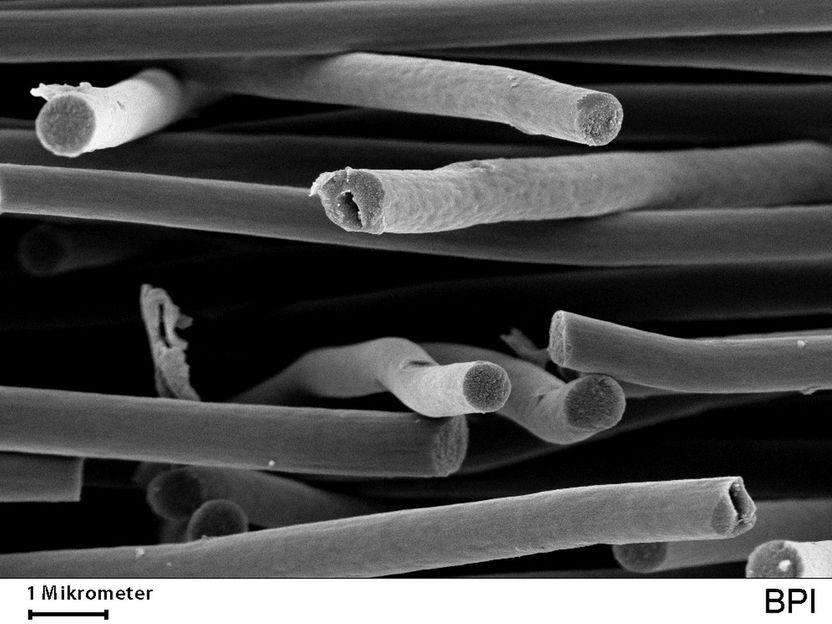

Two novel testing facilities for materials research will be provided to the Technical University of Braunschweig and Hamburg University of Technology by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation). For the first time in a university environment, these two major instruments totalling 3.4 million euros will allow researchers to investigate, under realistic stress conditions, the failure mechanisms of large automobile and aircraft components (panels) made of fibre-reinforced composite materials. Until now, this research objective could only be pursued using small laboratory samples, with computers unable to provide adequate simulations.

Components made of fibre-reinforced composites, such as aircraft and automobile body parts, can be designed to be stronger or more rigid than metal-based components. An additional benefit is the option to integrate material-monitoring sensors directly into the component. This could make driving and flying cheaper and safer, as well as more energy-efficient.

"Fibre-reinforced composites have been used rather conservatively in automotive and aircraft engineering," says Burkhard Jahnen from the DFG Engineering Sciences Division, who is in charge of coordinating the DFG's new major-instrumentation initiative. "Because engineers are reluctant to go to the limits of composites and lack sufficient data on how these materials fatigue in long-term use, they tend to design components made of these materials rather generously — which makes aeroplanes, for example, heavier than necessary. That's why the groundbreaking designs that would be possible with fibre composites are still waiting in the starting blocks."

But the findings enabled by the new testing facilities could change this. Up to 60 tons heavy, 6 metres wide and 6.6 metres tall, these large instruments will introduce previously unavailable technology to basic research in Germany. The testing equipment in Hamburg, for example, can expose entire aircraft body segments to the kind of vibration they would be exposed to in air traffic. Thus the knowledge transfer between basic materials research and practical application can close a central gap.

Out of ten funding proposals submitted under the DFG's major-instrumentation initiative, the two proposals from Braunschweig and Hamburg-Harburg were selected because their interdisciplinary approaches proved most convincing to the international team of reviewers. The new testing facilities will also be made available to researchers from other universities investigating fibre-reinforced composites.

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.