Making enzymes fit for industrial applications

Biobased process for ammonia production

Advertisement

Bacterial enzymes are often powerful but also very sensitive catalysts. To call up their performance, they therefore need a special environment.

Together with their research partners, the team at the Center for Electrochemistry is working on the development of new catalysts.

© RUB, Marquard

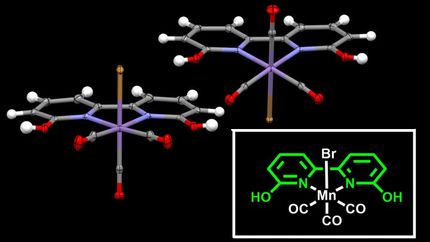

Researchers at Ruhr-Universität Bochum (RUB) have developed new techniques for efficiently coupling bacterial enzymes to electrodes. Together with a team from the University of Utah, they realised a system for ammonia synthesis based on a nitrogenase enzyme. They also designed a hydrogen/oxygen biofuel cell based on a hydrogenase enzyme together with a team from the Max Planck Institute for Chemical Energy Conversion. Both papers have been published in the journal “Angewandte Chemie” in May and June 2020.

Powerful enzymes require special conditions

Many enzymes that occur in nature are powerful catalysts, such as the so-called [FeFe]-hydrogenases. Hydrogenases are used by bacteria to produce hydrogen, while nitrogenases succeed in activating the strongest bond in nature in nitrogen (N2). Both enzymes are highly sensitive to oxygen, but use readily available non-precious metals in their active centres. Thus they could one day replace expensive precious metal catalysts. “To use such highly sensitive catalysts for biofuel cells is still one of the biggest challenges in sustainable energy conversion,” says Professor Wolfgang Schuhmann, head of the RUB Centre for Electrochemistry and member of the cluster of excellence “Ruhr Explores Solvation”, Resolv.

Biofuel cell realized with enzyme

In cooperation with the team of Professor Wolfgang Lubitz from the Max Planck Institute for Chemical Energy Conversion in Mülheim an der Ruhr, the Bochum group showed under which circumstances this is nevertheless possible. They used a so-called [FeFe] hydrogenase from the bacterium Desulfovibrio desulfuricans. Although this is a very efficient catalyst, it must be protected in the fuel cell from the oxygen required for operation at the second electrode.

In this work, the scientists integrated the [FeFe]-hydrogenase for the first time into a biofuel cell operated with so-called gas diffusion electrodes. In this cell, hydrogen and oxygen are transported to the enzymes through a membrane. The team embedded the enzyme in a matrix consisting of a so-called redox polymer, which fixes the enzyme to the gas-permeable electrode surface, protects the enzyme from the harmful effects of oxygen and also establishes electrical contact between the enzyme and the electrode. With this design, the fuel cell achieved previously unattained high current densities of 14 milliamperes per square centimetre and high power densities of 5.4 milliwatts per square centimetre.

Biobased process for ammonia production

In the second project, the research team at RUB, together with the US group led by Professor Shelley Minteer from the University of Salt-Lake City, looked for a bioelectrosynthetic alternative for ammonia synthesis. In the chemical industry, ammonia is commonly produced using the Haber-Bosch process at high temperature and high pressure and with a considerable release of CO2.

Some bacteria possess enzymes, called nitrogenases, with which they fix molecular nitrogen (N2) and can metabolise it at room temperature and without increased pressure. However, in living organisms this consumes a lot of energy in the form of the energy storage molecules ATP.

The research team showed that it is possible to couple the nitrogenase from the bacterium Azotobacter vinelandii with an electrode through which the necessary electrons for the reaction can be supplied, so that no ATP is required. Once again, the key to success was a redox polymer that helped to establish a stable and efficient electrical contact between the electrode and the nitrogenase/redox polymer composite. “To our knowledge, the fixation and contacting of nitrogenases in redox polymers is the first step in making nitrogenases applicable for bioelectrosynthesis,” write the authors of the study.

Original publication

Julian Szczesny, James A. Birrell, Felipe Conzuelo, Wolfgang Lubitz, Adrian Ruff, Wolfgang Schuhmann; "Redox‐Polymer‐Based High‐Current‐Density Gas‐Diffusion H2‐Oxidation Bioanode Using [FeFe] Hydrogenase from Desulfovibrio desulfuricans in a Membrane‐free Biofuel Cell" Angewandte Chemie International Edition; 2020

Yoo Seok Lee, Adrian Ruff, Rong Cai, Koun Lim, Wolfgang Schuhmann, Shelley D. Minteer; "Electroenzymatic Nitrogen Fixation Using a MoFe Protein System Immobilized in an Organic Redox Polymer"; Angewandte Chemie International Edition; 2020

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.