LLNL receives Recovery Act funding for carbon capture technology

Advertisement

New and existing coal-fired power plants could more easily capture carbon dioxide emissions with help from Lawrence Livermore National Laboratory researchers.

With more than $3.6 million in Recovery Act funding, LLNL researchers, in partnership with the University of Illinois and Babcock & Wilcox, will develop synthetic small-molecule catalysts that greatly speed the absorption of carbon dioxide (CO2) into liquid solvents that enable them to bind CO2 less tightly and reduce the energy required to release the CO2 from the solvent afterward.

This will open up a new range of process conditions and methods for industrial CO2 capture, ranging from near-term improvement of existing processes to new capture technologies in the longer term.

"At the highest level, this will speed up systems that absorb CO2 from flue gas," said Roger Aines, LLNL's Carbon Fuel Cycle program leader

The team is replicating one of the fastest enzymes known - carbonic anhydrase - which is important in the human body. This enzyme speeds up the rate in which CO2 is hydrated.

"It's the reason you can breathe," Aines said. "We're making small molecules that perform that same function but that can survive in an industrial process where an enzyme is food. They speed up the reaction."

The catalysts have already been developed in the biomedical field but need to be enhanced to provide industrial robustness against thermal and chemical degradation.

The work will combine LLNL's scientific experience in creating synthetic small-molecule catalysts with Babcock & Wilcox' industrial experience and testing to design, synthesize and demonstrate use of the catalysts in both existing and new CO2-capture systems.

The three-year project received $3.6 million in funding from DOE's Advanced Research Projects Agency-Energy (ARPA-E), and Babcock & Wilcox will supply their own research and testing costs.

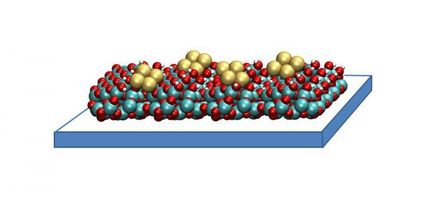

The team will develop three systems: dissolved catalyst systems, which can be immediately applied to industrial practice; tethered catalyst systems, which promise very high efficiency but may require changes in industrial practices; and catalyst-enhanced encapsulated systems, which use liquid solvents enclosed in very thin membrane coats that may represent an entirely new type of carbon capture system.

Under the first year of a Laboratory Directed Research and Development project, the team is developing the catalysts for this CO2 function. The ARPA-E funding will move the project even further out to industry.

"This project supports ARPA-E's goal to have a transformational impact on dramatically lowering the energy and cost penalties associated with carbon capture, and in the long run, reduce the problem of energy-related emissions of greenhouse gases," Aines said.

The Laboratory's computational tools will be used to test catalyst designs to ensure long-term stability - structural stability and preservation of the metal ion in the catalytic pocket. This testing is typically a slow, arduous process, but with LLNL's supercomputers, the team will be able to test hundreds of candidate compounds, produce dozens for bench testing and in only two years be ready for long-term stability tests in large-scale testing facilities, Aines said.