The bat is the godfather of digital transformation

Saving resources with the virtual paint lab

Advertisement

Digital simulations instead of trial and error: In the PaintVisco project, researchers at the IPA are modeling the development and processing of paints. The data for this is provided by a newly designed rheometer, which for the first time can be used to precisely measure the viscoelastic properties of paints during drying and curing - the model for the technology development was the bat's echolocation.

Symbol image

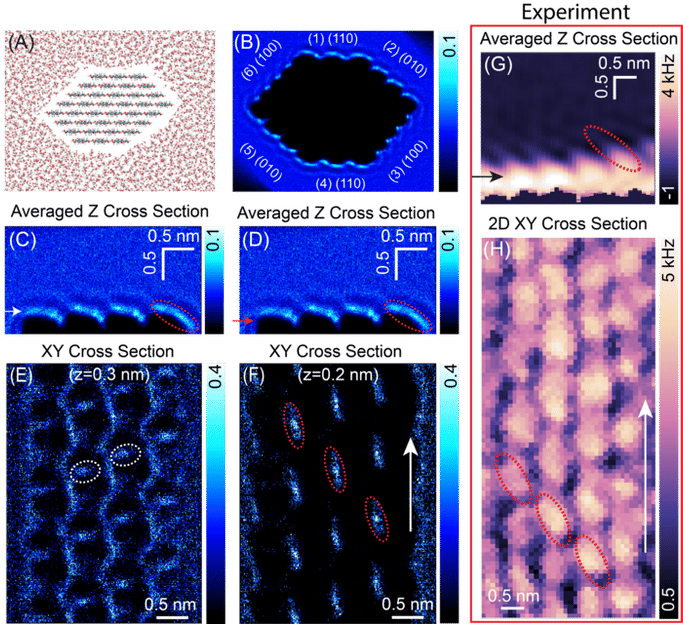

Computer generated picture

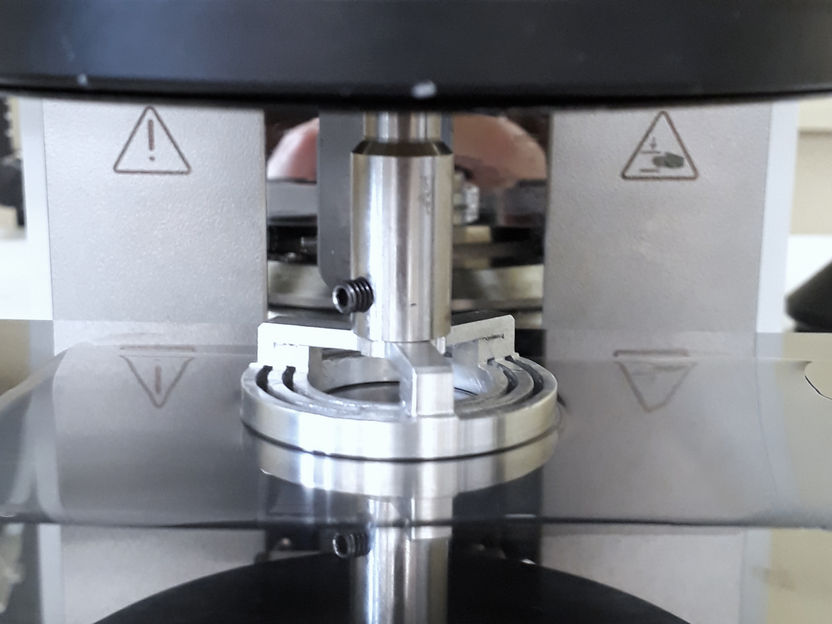

Converted meter

Fraunhofer IPA

How long does the coating remain flowable? How well does it level out unevenness? Under what conditions does the desired, mirror-smooth surface form? "Until now, painters have had to try out when a paint layer runs optimally in costly and time-consuming trial-and-error experiments," explains Dr. Fabian Seeler. In the PaintVisco project, he has now developed a simulation program that can be used to virtually determine the properties of coatings.

Developing the computer model was a real challenge for the IPA researcher and his team, because paints are viscoelastic. This means that - depending on time and temperature - they change their properties: At first they behave more like liquids, later more like solids. The viscoelasticity, in turn, is crucial for predicting the flow, i.e. the ability of a coating to compensate for unevenness - this can be surface brush marks, but also pores, wave structures and edges under the coating layer.

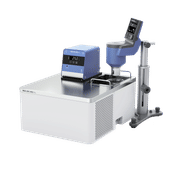

A new measuring technique provides the data

To simulate this very complex behavior of coatings, a wealth of data is needed. The measuring instruments that are to provide this are called rotational rheometers. They determine the flowability of paints by causing a thin liquid paint sample to rotate or vibrate with a disk attached, and then measure what force is needed to deform it. "However, previous devices prevent the solvents from evaporating, so the results are of limited use to the coatings industry. In addition, such measurements always show only a small arbitrarily selected section of the material behavior, since measurements are often made with only a single vibration frequency," Seeler reports. For computational projections, however, one needs much more comprehensive information about the material behavior, for example the behavior of a paint sample at numerous frequencies.

Together with his team, he developed a new measurement technique. Nature was the inspiration: "We copied the measuring principle from the bat," recalls the researcher. The bat uses short ultrasonic calls for orientation: each call contains low and high frequencies that flow into one another and are reflected by the environment. From the echo, the bat recognizes, for example, where obstacles or prey are located. By repeating the call, the bat can track how the distance to an obstacle changes over time or how the prey animal moves.

Like the bat, the PaintVisco rheometer works with smoothly merging frequencies. However, it is not ultrasonic calls that are varied, but the frequencies at which the paint sample is deformed. By repeating the sequence of frequencies, the change in viscoelastic paint properties during setting can be recorded. This special signal form makes it possible to determine all the data needed for progression prediction within a very short time, Seeler emphasizes.

With the new measuring technique, the researchers at the IPA can now also take into account solvent evaporation, which is so important for industry: In their rheometer, the paint layer is no longer deformed by a closed disk, but by a construction of several rings. The openings between the rings allow the solvent to evaporate.

"Our measurements have shown that the multifrequency measurement technique can be used to determine the change in the viscoelastic properties of the paint layer over the entire coating process - from application to drying at room temperature to curing in an oven," Seeler reports. "With the help of this data, we can now not only understand the changes in the material properties of a paint layer that determine its course during curing, but also make digital course predictions and derive optimized paint properties - regardless of whether the paint surfaces were created with a brush or an atomizer."

Simulations that save resources

Developing and introducing a new paint takes several years and costs millions of dollars. In the future, PaintVisco simulations can help manufacturers optimize the performance of their paints at the development stage, bring new products to market faster, and provide them with additional information for users. Detailed information would help paint stores to save on expensive test runs and thus achieve optimum results more quickly - advantages that can be decisive for competition in times of rising gas or electricity prices and staff shortages.

Awards

Awards already underline how important the project results are for industry. Dr. Fabian Seeler supervised the student thesis of Nicolas Keinath. It was awarded the Esslingen University of Applied Sciences graduate prize donated by the coatings manufacturer Mankiewicz. Together with Dr. Oliver Tiedje, Seeler also received the Coatings Chemistry Award of the German Chemical Society.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Rheology

Rheology deals with the flow behavior and deformation properties of materials. In the chemical field, it is indispensable for understanding the consistency, viscosity and elasticity of liquids, gels and solids. Whether formulating paints, producing polymers or optimizing food textures, rheological properties influence how substances react, move and feel.

Topic world Rheology

Rheology deals with the flow behavior and deformation properties of materials. In the chemical field, it is indispensable for understanding the consistency, viscosity and elasticity of liquids, gels and solids. Whether formulating paints, producing polymers or optimizing food textures, rheological properties influence how substances react, move and feel.