It takes more than an active ingredient to make a medicine

Advertisement

Just press the tablet out of the pack and wash it down with a drink of water - medicines are part of everyday life, whether taken to dispel headaches, lower blood pressure or combat infections. But not only the development of a new active ingredient requires intensive research activities. About 15 per cent of the price of a medicine is due to the tricks and techniques employed to ensure it reaches its intended destination in the body. All administration forms of modern medicines are the ingenious products of a special research area: pharmaceutical technology, also known as galenics after the Greek physician Galen.

The challenges faced by Galen's heirs are numerous and different for every active agent - masking a bitter taste is one of the easier exercises. Things become more difficult with drugs that refuse to dissolve in the body's aqueous environment. Some tablets are only allowed to release their active ingredient on reaching the intestine, while sustained-release tablets are designed to permit only gradual drug dissolution to maintain a consistent dose level in the blood - without which patients would have to remember every few hours to take their medication.

"BASF offers pharmaceutical manufacturers a full range of excipients to help turn promising active agents into successful medications", explains Dr. Jan-Peter Mittwollen of Strategic Marketing for Pharmaceutical Excipients at BASF. "Polymers, i.e. chains of molecules consisting of identical building blocks are particularly relevant in this respect. Our Kollidon® products, for example, are based on the particularly stable polyvinylpyrrolidones".

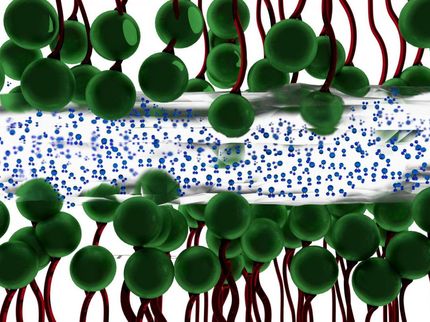

Each active ingredient places different demands on pharmaceutical technology: acid-sensitive drugs, for example, have to be protected against the aggressive gastric fluids - a task for the protective coat made of Kollicoat® MAE, which encloses either a complete tablet or the individual pellets inside a gelatin capsule. These capsules can also be filled with combinations of differently prepared pellets which release part of the active ingredient while still in the stomach and the other part only later on reaching the intestine.

Mittwollen is particularly proud of Kollicoat® SR 30 D. "Matrix tablets made from this novel mixture of polymers do away with the need for frequent repeat dosing". The sustained-release tablet takes about 24 hours to release its content of active ingredient completely and at a steady rate, a particularly important requirement for antihypertensive drugs or hormone preparations.

BASF's range of products also includes a large number of other substances such as solubilizers which create a bond between lipophilic (fat-loving) drugs and water. Besides all the medical and chemical requirements placed on active agents and excipients, however, it is always important not to neglect one other aspect: active agents and excipients must be easy to process.

The pharmaceutical industry posts annual sales of around 3.6 billion Euros with excipients - with BASF among the world's top five excipient manufacturers. The highest selling products: the polyvinylpyrrolidone based Kollidon® brands used as binders and granulating agents. The most important sales regions besides Europe are the USA and Asia where the excipient market is currently experiencing rapid growth. China, for example, looks set to be among the three biggest net exporters of pharmaceutical products in the next three to five years with licensed production of a range of standard products.