Walnut shells as ingredients for cosmetics

Search for alternatives to microplastics

Advertisement

Banned throughout the EU since October 2023: microplastics in all cosmetic products and detergents. But what alternatives are there? Researchers at Rhine-Waal University of Applied Sciences (HSRW) want to find out together with the family-run company bb med. product GmbH from the Lower Rhine region.

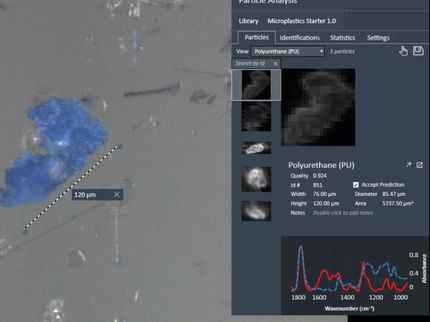

Microplastics have so far been added to cosmetic products (e.g. shower or facial scrubs) or detergents (washing and cleaning agents) as abrasives and opacifiers. These are water-insoluble, solid plastics that are five millimetres or smaller. Dermatologists sometimes emphasize that exfoliation is not necessary for healthy skin, but who hasn't experienced the pleasantly soft feeling on the skin after exfoliation?

The problem with added microplastics is that the particles enter the wastewater during the washing process. The particles that are washed into the sewage system are so small that sewage treatment plants are unable to filter them. In wastewater treatment plants, the wastewater undergoes a multi-stage purification process: Solids are removed, UV light kills germs and membrane systems filter bacteria and viruses. With their multi-stage purification process, sewage treatment plants are not designed for micropollutants. This includes microplastics. For this reason, with the REACH chemicals regulation, the EU has put a stop to the use of microplastics in products whose residues end up in wastewater but still leave the sewage treatment plant after the purification process and end up in bodies of water.

Even if the proportion of microplastics that end up in wastewater through scrubs or detergents is quite low, research into alternatives is a start. bb med. managing director Robert Beinio is aware of this responsibility: "We have not been using microplastics for a long time. And the umbrella organization of European cosmetics associations also recommended back in 2015 that plastic particles should no longer be used in cosmetics," he emphasizes. Nevertheless, Robert Beinio and Dr. Dirk Bockmühl, Professor of Hygiene and Microbiology at the HSRW, have set themselves the goal of using natural alternatives. "We are taking a closer look at one of them in our project: walnut shells," says the professor from the Faculty of Life Sciences.

To gain a better understanding of this, the trip is going to Kyrgyzstan: "The country has great, natural walnut forests, the sustainable use of which we can ensure in the SUFACHAIN project. We also want to take into account the by-products of the walnut harvest. As part of the project, we want to investigate the technological challenges of this potential use - in particular the grinding process to achieve non-sharp-edged particles and the microbiological quality - and find solutions," says Bockmühl, explaining the research project's approach.

There are a few hurdles to overcome in order to support the Kyrgyz farmers. Bockmühl is also aware of this: "Walnut shells, as well as the apricot kernel shells also being studied in the project, are repeatedly exposed to microbial contamination during growth, harvesting and further processing, for example by mold fungi. In order to obtain a safe cosmetic ingredient, these microbiological problems must be recognized and solved. We want to do this in the project in such a way that the products can be processed with the least possible use of biocides and without the use of potentially problematic treatment methods such as irradiation. To this end, we primarily want to optimize process steps in Kyrgyzstan with our local partners, but also develop possible, low-risk preservation methods," says the HSRW professor.

And before such a product can be marketed, there is also a lot to consider in terms of product safety: "In the case of a peeling product with core flours, for example, the sharpness of the particles is important. Depending on the origin of the particles and the degree of grinding, they may be suitable for use on the face or rather for a foot peeling," says the Kalkar-based entrepreneur Beinio. "The product also has to pass a storage test at different temperatures, known as the stability test. This is an accelerated ageing process. Then the microbiological safety is tested by means of a preservation stress test. For the safety of the buyers using the product, a toxicological report is drawn up and a dermatological test is carried out," explains Bockmühl. Beinio adds that the various natural cosmetics labels and their requirements for certification also play an important role.

According to Bockmühl, the aim of the project is to develop a cosmetic ingredient, not a finished cosmetic. The project concept, which involves working with final formulations, means that application is actually possible quite quickly after successful completion of the project. On the other hand, the project also aims to "open up ways for Kyrgyz farmers to market walnut shells, which would otherwise be a pure waste product. From a scientific and industrial point of view, we want to open up opportunities to overcome the technological hurdles mentioned by mapping and scientifically supporting the entire product development process from the walnut shell ingredient to the finished cosmetic with regard to the Kyrgyz products. Ultimately, the aim is for farmers to optimize their added value in the future by marketing high-quality products - including those made from current food production waste," says the HSRW professor, summarizing the project.

The SUFACHAIN project aims to create a win-win-win situation in line with the three pillars of sustainable management: Ecology, economy and social issues. A waste product is further processed, thereby supporting farmers economically. And a company from Kalkar on the Lower Rhine benefits from soon being able to launch more sustainable products on the market.

Even if the development of a cosmetic product, including all the necessary tests, can take a year or even longer: The knowledge and experience gained from the project is not only important in the Lower Rhine region and Kyrgyzstan - manufacturers from all over Europe could benefit from it.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.