Researchers develop cleaner, scalable process to recycle lithium-ion batteries

"We’ve shown that it’s possible to create high-performance batteries from recycled materials at scale"

Advertisement

In a major step forward for sustainable energy technology, researchers at Worcester Polytechnic Institute (WPI), led by Professor Yan Wang, William B. Smith Professor of Mechanical and Materials Engineering, have developed a new, scalable method to recycle lithium-ion batteries in a way that is both efficient and environmentally friendly.

WPI Professor Yan Wang leads the team who developed the new process.

Worcester Polytechnic Institute

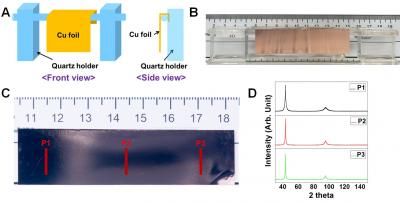

The team’s research, titled "Upcycling Mixed Spent Ni-Lean Cathodes into Ni-Rich Polycrystalline Cathodes", was recently published in Energy Storage Materials, a multidisciplinary peer-reviewed journal focused on the topics of materials and energy. The paper details an innovative hydrometallurgical upcycling approach that offers both environmental and performance advantages over traditional recycling methods.

The process specifically targets spent mixed nickel-lean (Ni-lean) cathode materials, which are commonly found in used lithium-ion batteries. Traditional recycling methods struggle to recover these materials effectively and often rely on energy-intensive processes that produce lower-value outputs. In contrast, Wang’s approach recovers more than 92% of critical metals—nickel, cobalt, and manganese—and turns them into high-performance cathode powders.

Testing shows that batteries made with these recycled materials perform on par with those made from virgin materials, retaining 88% of their capacity after 500 charge cycles and over 85% capacity after 900 cycles in commercial-scale pouch cells. The new process also uses 8.6% less energy than conventional hydrometallurgical methods and significantly reduces carbon emissions—by 13.9% when compared with traditional recycling, slightly more than with direct upcycling.

“This work not only addresses the environmental challenges of battery waste but also helps reduce our dependence on mining for critical materials,” said Wang. “We’ve shown that it’s possible to create high-performance batteries from recycled materials at scale, which is essential for building a more sustainable and resilient battery supply chain.”

This innovation directly tackles two major challenges: the growing volume of battery waste and the global demand for critical materials used in electric vehicles and other clean energy technologies. With industry and policymakers focused on sustainable solutions, this advancement could play a key role in building a more circular and climate-conscious battery economy.

Original publication

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.