Fraunhofer FEP presents new vacuum coating processes

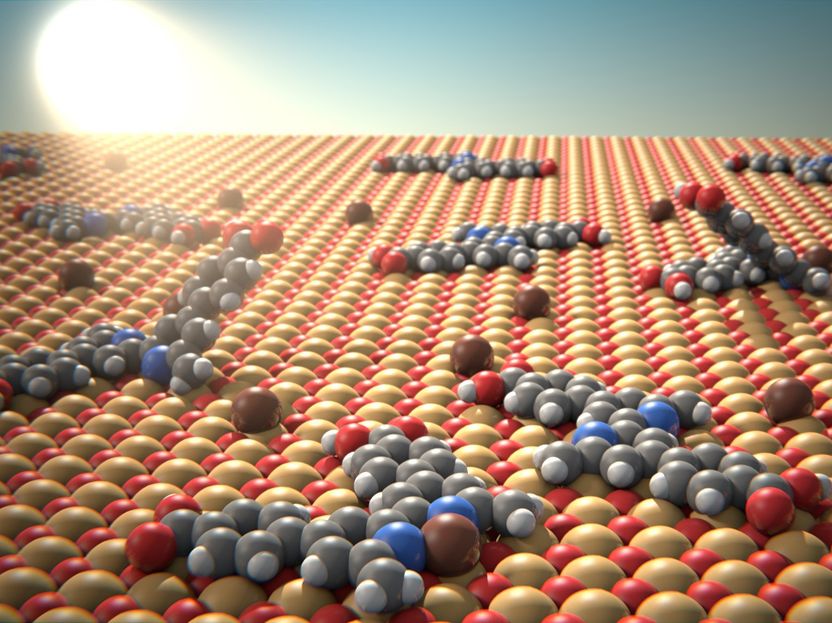

The Fraunhofer Institute for Electron Beam and Plasma Technology FEP presents a new and highly efficient processes for coating of large areas, such as arcPECVD (hollow cathode arc PECVD), plasma-activated high-rate evaporation using a dual crucible and the sputtering of Indium-free transparent conductive coatings. All three technologies are ready for industrial utilization.

Highly efficient vacuum coating process of Fraunhofer FEP

Fraunhofer FEP

Fraunhofer FEP in recent years advanced the deposition of niobium-doped titanium oxide layers as an Indium-free alternative for transparent conductive electrodes towards an industrially feasible and cost-efficient process. Thus, the glass refinement can be applied in a stable and reproducible process onto large-area surfaces.

Furthermore, Fraunhofer FEP has developed the arcPECVD process, a roll-to-roll low-pressure technology with very high coating rates, which can be combined easily with other vacuum processes in one web coater due to the low working pressure. Achieving a very good productivity of over 2000 nm∙m/min, barrier layer systems with an extremely high barrier property can be obtained in one pass. However, also other layers, such as siliceous interlayers for reducing layer tension in optical layer stacks have been already realized.

Introducing the dual crucible for the plasma-activated high-rate deposition Fraunhofer FEP succeeded in developing a powerful plasma process with long-term stability for coating relatively thick layers of high melting point materials in an economical way.

Most read news

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Category:Swedish_mineralogists

Cleaner and greener cities with integrated transparent solar cells - High power conversion of new solar cells that are thin, flexible, and transparent makes them ideal for a wealth of new applications

Category:Triarylmethane_dyes

Magnetism without metal: a milestone for materials science - “This is fundamentally new”

Category:Cycloalkenes

BASF concerned about the effects of high benzene prices on demand for plastics - Business to be turned down if necessary

Amine