Soft magnetic material characterizations get a harder look

Advertisement

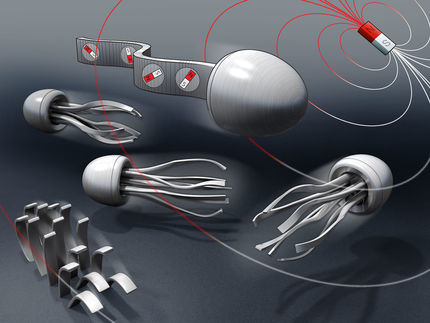

In motors, generators and similar electric machines, the electrical current that powers them generates magnetic fields that magnetize some of the metallic components.

This is an image of an electrical machine, sliced open to show the rotor and stator iron lamination, which consists of soft magnetic material.

Image courtesy of Silas Elfgen

Choosing the right magnetic material is crucial for designing efficient machines, so researchers from the Institute of Electrical Machines (IEM) at RWTH Aachen University in Germany analyzed the existing system for characterizing soft magnetic materials, which are easily magnetized. To identify a better system for quality control, they looked at several factors that can affect the uncertainty inherent in the measurement of magnetic properties.

One example of a soft magnetic material manufacturers use to make generators, electric motors and transformers is low carbon steel. Generally, these materials serve the purpose of guiding and amplifying the magnetic flux when converting between mechanical and electrical energy in these machines. Magnetic measurements allow manufacturers to characterize those materials and to calculate how much power will be lost due to the magnetization process.

"Manufacturing processes such as the cutting of the steel lamination influence the behavior of the soft magnetic material," said Silas Elfgen of RWTH Aachen University. "Therefore such influence has to be measured and we must be able to model such parasitic effects."

Standardized methods for evaluating magnetic properties exist, but the researchers found them to be inadequate for applications such as designing traction drives in vehicles. They used one of the standard testing instruments, called a single sheet tester, to characterize soft magnetic materials across a range of frequencies and magnetic flux densities.

Their tests showed that the currently used parameters describing measurement qualities are not sufficient for accurately evaluating uncertainties that arise at frequencies and magnetization levels of some applications currently of interest. They also looked at additional factors that influence the characterization and measured how much each parameter contributes to the uncertainty. They propose that these uncertainties can guide the selection of the most appropriate soft magnetic material for a specific electrical machine.

"These analyses can be used by everyone working with magnetic characteristics and magnetic model parameters," Elfgen said. "Further, it can be used in quality assurance of a product to define production features."