Discovering new field affecting metals solidification

Advertisement

A fundamental discovery that alters our current understanding of how metals solidify and form crystalline patterns may help lead to better control of casting and welding processes. It also explains how snowflakes and many mineral patterns form naturally.

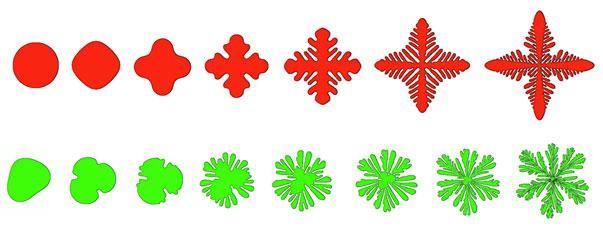

When testing crystalline (red) and fluid (green) materials in an environment free of noise -- sound vibration or disturbances that are known to act upon a solidifying material -- scientists at Florida Tech and Arizona State University discovered that a previously unknown field modulated the speed and shape of the crystal-melt interface, leading to the pictured pattern formations.

Martin Glicksman/Florida Institute of Technology

Reexamining data from his 20-year-old NASA experiment involving the repeated freezing and melting of high-purity materials in microgravity, Martin Glicksman, research professor in materials science and the Allen Henry Chair at Florida Institute of Technology, working with Kumar Ankit at the School of Matter, Transport and Energy at Arizona State University, discovered the way nature guides formation of complex patterns in materials that crystallize.

Glicksman discovered an energy field affecting all crystallizing substances, which he labeled the bias field that he believes is nature's way of guiding cellular and branching dendritic microstructures that form during solidification of most metals and alloys.

"In the last phases of melting, needle-like crystals suddenly changed to spheres, and so for the first time ever, as we watched stationary particles melting in microgravity and observed their rather remarkable shape change," Glicksman said.

"I said," he added, "'There must be something more going on than just noise.'"

Previously, and still, many scientists believe that what causes pattern formation is random noise - any sound vibration or disturbances that act upon a solidifying material. Glicksman and Ankit have found a subtle internal energy source- the bias field-occurs that actually modulates the speed of the solid/liquid interface on small scales and ends up creating remarkably complex structures. That finding has been confirmed theoretically and though advanced simulation methods.

"We were fortunate to perform experiments in microgravity, where the bias field idea was initially suggested to explain the occurrence of unusual melting patterns," Glicksman said. "Now we have a sound thermodynamic theory and proof to back that idea up."

Glicksman and Ankit recently published their findings proving the existence of bias fields.

Because the process of solidifying metals produces branch-like internal micro-patterns that disturb the chemical homogeneity of cast materials, having a better understanding of the bias field's role in their formation opens pathways for engineers to make improvements in cast and welded materials commonly used in everything from automobiles and airplanes to medical instruments.

"If we expect improvements in the structure of castings, weldments and other solidification processes, we've got to know and apply the correct physics," Glicksman said. "This discovery potentially could lead to metallurgical process improvements."