Fraunhofer presents high-speed microscope with intuitive gesture control

Advertisement

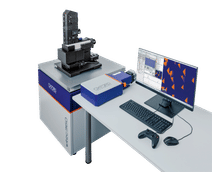

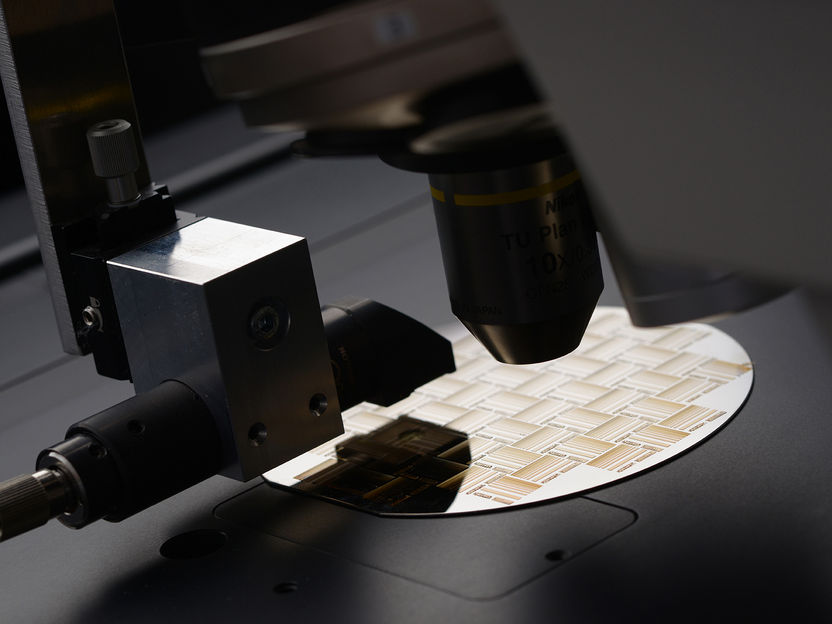

The Fraunhofer Institute for Production Technology IPT in Aachen has developed a high-speed microscope for quality control of large-area objects for the semiconductor and electronics industries or for rapid testing of biological samples. The microscope digitizes samples with up to 500 frames per second. At Control, the international trade fair for quality assurance, from 7 to 10 May 2019 in Stuttgart, the metrology experts from Aachen will be demonstrating for the first time how this system can be combined with gesture control by means of smart glasses and thus controlled and operated even more efficiently.

The high-speed microscope digitizes samples at up to 500 frames per second and can be combined with gesture control using Smart Glasses for even more efficient control and operation.

© Fraunhofer IPT

Conventional microscope images of large components often take such a long time at high magnifications that 100 percent inspections cannot be performed due to time constraints and only random samples can be examined. For this reason, the Fraunhofer IPT has developed a new imaging process that combines a large number of images into a comprehensive overall image: The microscope stage moves the object continuously during the entire process in order to digitize the sample at very high frame rates. Since each object is only exposed extremely briefly with a flash, the shot is free of motion blur and is sharp at every point thanks to real-time hardware autofocus systems.

The additional Smart Glasses consist of data glasses that enrich the user's environment with virtual elements. The glasses are connected to a sensor for gesture recognition: If the user holds his hand over this sensor, he can not only see the image, but also move and focus the microscope with intuitive hand movements. The visualization is browser-based – both smartphone and tablet can be integrated.

The high-resolution images of the high-speed microscope are combined to form a large overall image that the user can not only view, but also move, freeze and save. The scanning process combines real-time data handling with powerful image pre-processing, which runs almost without delay thanks to GPU support. Current developments also include machine learning approaches such as Deep Learning and Convolutional Neuronal Networks (CNN).

Other news from the department science

These products might interest you

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.