Fingerprint spectroscopy within a millisecond

Quality control in real time for the use in the pharmaceutical, chemical and food industry

Advertisement

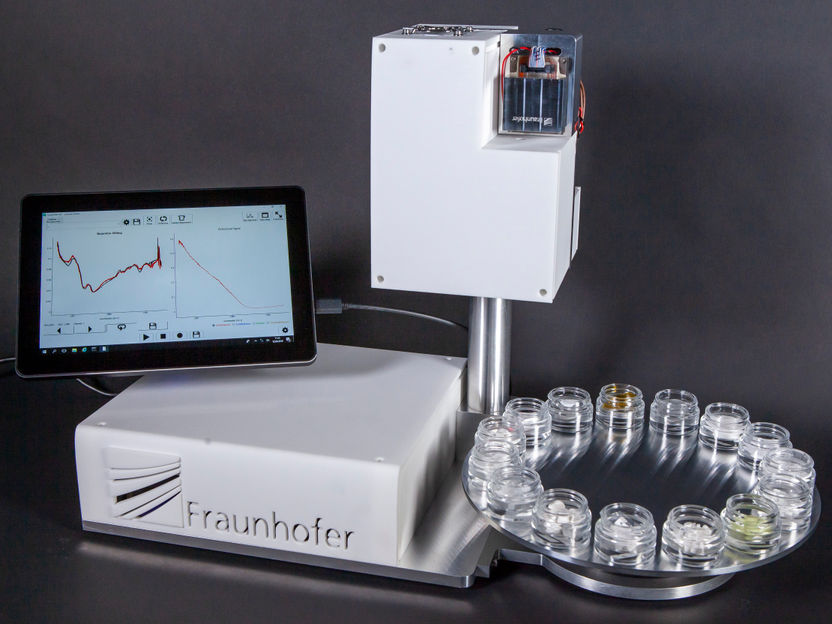

To guarantee high quality pharmaceuticals, manufacturers need not only to control the purity and concentration of their own products, but also those of their suppliers. Researchers at the Fraunhofer Institute for Applied Solid State Physics IAF have developed a measuring system capable of identifying a wide variety of chemical and pharmaceutical substances remotely and in real time. It is perfect for the use in the pharmaceutical, chemical and food industry.

Researchers of Fraunhofer IAF will present their demonstrator of the measuring system at this year’s LASER World of PHOTONICS.

© Fraunhofer IAF

Especially for pharmaceutical and food productions a continuous control of ingredients is indispensable. Usually, this would be done by a sampling and a laboratory analysis via chromatography or spectrometers. However, such a process is time-consuming and allows only for spot checks. At Fraunhofer IAF, researchers have developed a measuring system capable of a quality control in real time. It identifies even smallest amounts of substances based on their molecular composition.

Real-time measurements with quantum cascade lasers

The core of the system is an extremely fast tunable quantum cascade laser (QCL) operating in the mid-infrared range. Based on backscattering spectroscopy, the laser system not only allows to identify smallest amounts of chemical substances in real time, but also to continuously control chemical reaction processes. »Our measuring system allows for a remote identification of a wide variety of chemical and pharmaceutical substances. Time-consuming measurement procedures in laboratories can be replaced by real-time measurements during ongoing production processes«, explains Dr. Marko Härtelt, researcher at Fraunhofer IAF.

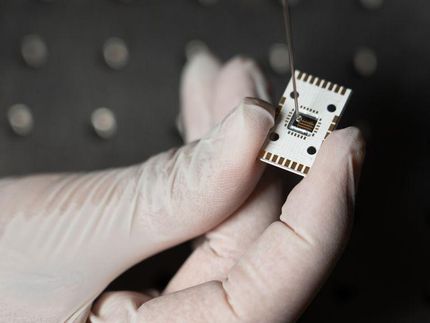

Together with his colleagues, he has been working on the development of QCLs for infrared spectroscopy for several years now. With the help of researchers of Fraunhofer IPMS, he has developed a compact and robust laser source with which the whole wavelength range of the QCL emitter can be scanned within a millisecond. The basis for this »fingerprint« method is the mid-infrared range (4-12 μm). »Many chemical compounds have a unique absorption behavior in this wavelength range, which is as unique as a human fingerprint«, comments Härtelt. The wavelength range enables a clear identification of the nature and composition of molecular compounds.

Extremely variable scan speed

Quantum cascade lasers developed by Fraunhofer IAF are characterized by their extremely variable scan speed, their compact size as well as their being widely tunable. The researchers have developed a QCL that can be tuned to work at high scan frequencies or in a quasi-static mode over a wide wavelength range. This is achieved through the combination of quantum cascade lasers in an external resonator with different MOEMS based lattice scanners that work as wave selective elements. »The fastest spectrally tunable resonant MOEMS scanners allow for the scanning of one thousand complete IR ranges per second. The high scanning speed is essential for applications in which the conditions change rapidly, such as the surveillance of chemical reaction processes or moving objects«, highlights Härtelt.

QCL based measuring systems are well suited for quality control at a variety of industrial sectors, thanks to their ability to identify various chemical substances remotely and in real time. Used in the pharmaceutical, chemical and food industry the measuring systems provide information about the authenticity and purity of substances at any given time during the production process. Furthermore, the quantum cascade lasers can be used in medical diagnostics or in the security sector to test hazardous substances,. Additionally, the compact design allows for the development of mobile, and even hand-held, measuring systems.