Electric vehicle batteries could get big boost with new polymer coating

Scientists enhance lithium-ion battery performance at the atomic level

Advertisement

Scientists at Lawrence Berkeley National Laboratory (Berkeley Lab) have developed a conductive polymer coating – called HOS-PFM – that could enable longer lasting, more powerful lithium-ion batteries for electric vehicles.

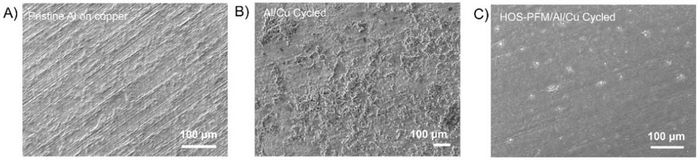

Berkeley Lab researchers demonstrated that the HOS-PFM coating significantly prevents aluminum-based electrodes from degrading during battery cycling while delivering high battery capacity over 300 cycles. From left: Scanning electron microscope images of aluminum on a copper bilayer device before battery cycling (Figure A) and after (Figure B). Figure C shows a copper tri-layer device with HOS-PFM coating after battery cycling.

Gao Liu/Berkeley Lab

Computer generated picture

“The advance opens up a new approach to developing EV batteries that are more affordable and easy to manufacture,“ said Gao Liu, a senior scientist in Berkeley Lab’sEnergy Technologies Area.

The HOS-PFM coating conducts both electrons and ions at the same time. This ensures battery stability and high charge/discharge rates while enhancing battery life. The coating also shows promise as a battery adhesive that could extend the lifetime of a lithium-ion battery from an average of 10 years to about 15 years, Liu added.

To demonstrate HOS-PFM’s superior conductive and adhesive properties, Liu and his team coated aluminum and silicon electrodes with HOS-PFM, and tested their performance in a lithium-ion battery setup.

Silicon and aluminum are promising electrode materials for lithium-ion batteries because of their potentially high energy storage capacity and lightweight profiles. But these cheap and abundant materials quickly wear down after multiple charge/discharge cycles.

During experiments at the Advanced Light Source and the Molecular Foundry, the researchers demonstrated that the HOS-PFM coating significantly prevents silicon- and aluminum-based electrodes from degrading during battery cycling while delivering high battery capacity over 300 cycles, a performance rate that’s on par with today’s state-of-the-art electrodes.

The results are impressive, Liu said, because silicon-based lithium-ion cells typically last for a limited number of charge/discharge cycles and calendar life. The researchers recently described these findings in the journal Nature Energy.

The HOS-PFM coating could allow the use of electrodes containing as much as 80% silicon. Such high silicon content could increase the energy density of lithium-ion batteries by at least 30%, Liu said. And because silicon is cheaper than graphite, the standard material for electrodes today, cheaper batteries could significantly increase the availability of entry-level electric vehicles, he added.

The team next plans to work with companies to scale up HOS-PFM for mass manufacturing.

Original publication

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.