Porous silicon layers for more efficient lithium-ion batteries

Advertisement

The Fraunhofer FEP has developed coating processes for industry for several years. Recently in the project PoSiBat, Fraunhofer FEP scientists were able to develop a non-toxic and efficient manufacturing process for porous silicon layers. The results of the recently completed project will be presented at the Thin Film Technology for Energy Systems workshop at V 2019 and at the Fraunhofer FEP booth No. 22 (October 8 –10, 2019, in Dresden, Germany).

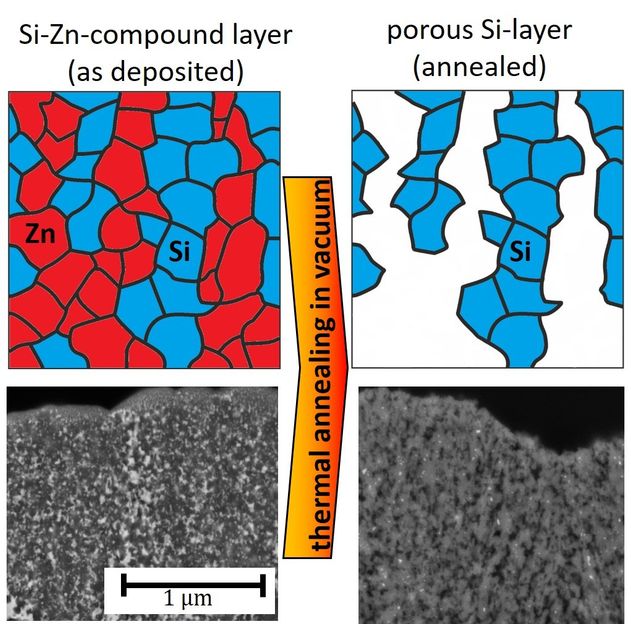

Scheme of the formation of separated grains of zinc (red) and silicon (blue) after deposition (left) and porous silicon film after expelling zinc by thermal annealing (right).

© Fraunhofer FEP

Lithium-ion batteries are well established due to their good properties. They have a higher energy density than other batteries. Therefore, they are used in cameras, watches, mobile devices and especially for electric vehicles. However, from a technical point of view they still offer a high potential for improving and optimizing of battery cells.

Lithium-ion batteries consist of an arrangement of different layers, each with different functions. The cathode and anode are the two electrodes of the battery, which are connected electrically via conductive electrolyte inside the cell. Currently, there are many research activities worldwide for developing new materials and alternative manufacturing processes in order to improve the battery performance, especially for mobile devices and electromobility. Important aspects for prospective technologies are resource conservation, environmental protection and safety. In addition, batteries should be produced sustainably and cost-effectively with large throughputs.

Within the project PoSiBat a cost-efficient and environmentally friendly process was developed for fabricating porous silicon layers as anode material. The replacement of currently used graphite materials by silicon promises an almost tenfold increase in the specific charging capacity of the anode. However, the charging and discharging process leads to an enormous change in volume of the silicon and therefore to a rapid mechanical and electrochemical destruction of the material compound and thus to cell failure.

Dr. Stefan Saager from Fraunhofer FEP explains the innovation: "We have developed a process in which silicon and zinc are simultaneously deposited on metal substrates. By applying a subsequent heat treatment, the zinc re-evaporates from the layer and pores are generated at the locations of former zinc grains. The porous structure in the silicon provides adequate space for its expansion during charging process and thus capacity fade is minimized. The porous structure can be manipulated and optimized to the specific battery requirements by adapting process parameters. The zinc can be collected and reused in the conceived process." The porous silicon layers show an encouraging battery performance, which is demonstrated by an initial charging capacity of more than 3,000 mAh/gSi and a comparably good cycle stability.

The expertise of the Fraunhofer FEP lies in the coating of metal substrates and foils with zinc and silicon, which is possible with very high coating rates in conventional non-toxic vacuum processes. These processes enable high throughput and low manufacturing costs. At the Fraunhofer Institute for Material and Beam Technology IWS, the electrochemical properties of the porous coatings were characterized.

The scientists at the Fraunhofer FEP are now looking forward to collaborating with battery manufacturers to transfere the results into high-performance products. They are open to cooperation.

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.