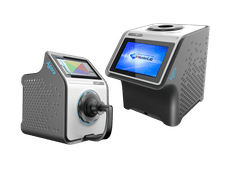

SPECTROTEST redefines mobile metal analysis

Advertisement

The new SPECTROTEST is a robust and simultaneously lightweight, high-tech instrument, which can be used as a universal industrial spectrometer for all metal testing applications: analysis of thin wires and samples with curved surfaces like cable or pipe, metal sorting at the shipping dock or identification of a wide range of different alloys at the scrap yard.

ICAL increases instrument uptime

In addition to the ergonomic design, the SPECTROTEST offers the greatest advantages through the interaction of new and proven components. ICAL (Intelligent Calibration Logic) is a completely novel system. The software-based system monitors and controls the state of the instrument independent from external influences. Thus, the time-consuming recalibration of the spectrometer can be eliminated. For change in location and temperature fluctuations, it is sufficient to measure a single control sample, which gives the user the benefit of significantly increased instrument uptime at the lowest operating costs.

The system offers the same advantages for measuring changing alloys: conventional industrial spectrometers sometimes require up to five samples and a corresponding number of individual measurements before the metal analyzer is set-up for a new alloy group, the optimum measurement program is loaded, and the most suitable excitation parameters are set. With the new function "APF Plus" (Automatic Program Finder) one measurement is sufficient: the system automatically recognizes the matrix and loads the most suitable program. Only SPECTROTEST has this function, that automatically selects the optimum parameters for the testing requirement at hand.

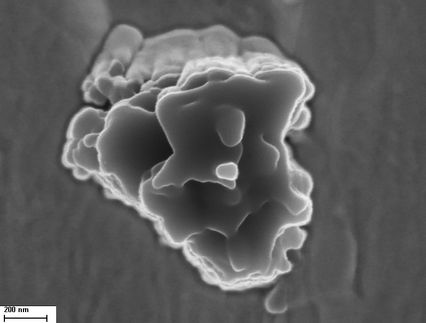

The optical system captures the entire relevant wavelength range with its CCD detectors and is distinguished by remarkable precision due to holographic gratings originating from SPECTRO's own production process. The gratings and CCD detectors are mounted in a fixed housing protected from dust and shock.

For the measurement, in addition to a standard spark probe for metal analysis, which can also be used for the determination of carbon, there is also a special probe with integrated UV optics. This allows the determination of the elements phosphor, sulfur, boron, and tin content in alloys. With only one charge of the battery installed in the trolley, several hundred measurements are possible.

Most read news

Organizations

Other news from the department research and development

These products might interest you

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.