Greener extraction of one of nature's whitest minerals

Advertisement

From medicine to make-up, plastics to paper - hardly a day goes by when we don't use titanium dioxide. Now researchers at the University of Leeds have developed a simpler, cheaper and greener method of extracting higher yields of one of this most useful and versatile of minerals.

Unfortunately, despite the mineral's relative abundance in nature, it's natural occurrence is never pure, being bound with contaminant metals such as iron, aluminium and radio-active elements. Pigment grade TiO2 is produced from mineral ore by smelting, then treating the slag with chlorine, or by directly introducing it into a sulphuric acid solution. These two processes generate toxic and hazardous wastes. The treatment of such wastes is expensive and complex.

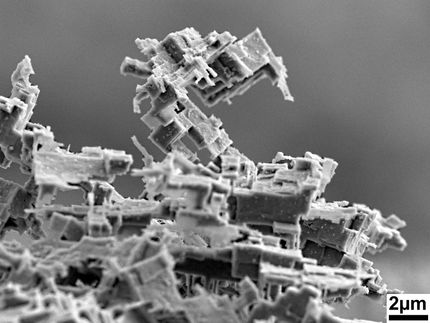

Prof Jha's patented process consists of roasting the mineral ore with alkali to remove the contaminants, which are washed and leached with acid to yield valuable by-products for the electronics industry. The coarse residue left behind is then reacted with 20 times less than the usual amount of chlorine to produce titanium dioxide powder.

The Leeds process gives an average yield of up to 97 per cent TiO2, compared with the current industry average of 85 per cent. This level of purity will reduce production costs of pigment grade materials and waste disposal costs. In addition, the process also recycles waste CO2 and heat.

Furthermore, Prof Jha is confident that the process can be further refined to yield 99 per cent pure titanium dioxide.

"Researchers have sought a sustainable replacement for current processes for many years," says Professor Animesh Jha, from the University's Faculty of Engineering. "Our aim was to develop new technology for complex minerals of titanium dioxide that are particularly low-grade and whilst readily available in the world market, can't yet be extracted economically," he says.

Most read news

Topics

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.